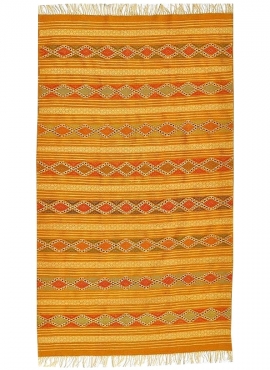

The first machine of mankind, the loom is a symbol of creativity and essential to the manufacture of rugs.

Blog categories

Search in blog

Latest posts

-

The loom: humanity's first machineRead more

The loom: humanity's first machineRead more -

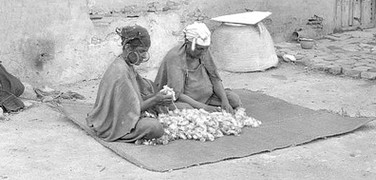

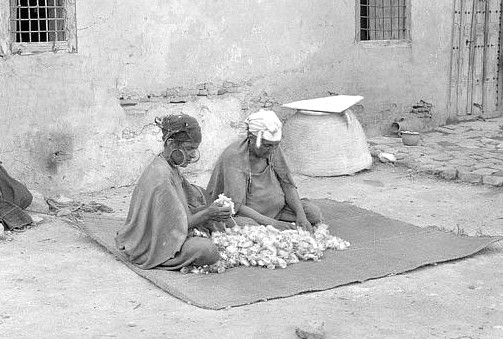

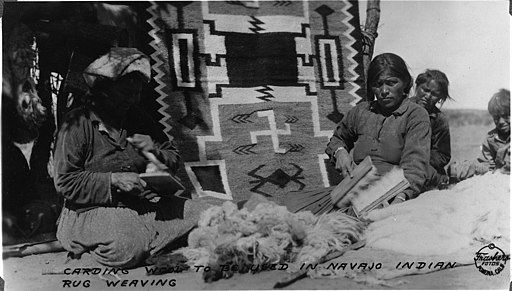

Preparing the wool13/11/2021Posted in: HandicraftRead more

Preparing the wool13/11/2021Posted in: HandicraftRead moreMany craftswomen still do all the work by hand, from shearing the wool to weaving, sorting the wool, cleaning,...

-

Floral waters / hydrolats in Tunisia: distillation and virtues29/01/2021Posted in: HandicraftRead more

Floral waters / hydrolats in Tunisia: distillation and virtues29/01/2021Posted in: HandicraftRead moreDiscovery of the artisanal method of distilling floral waters and their virtues.

-

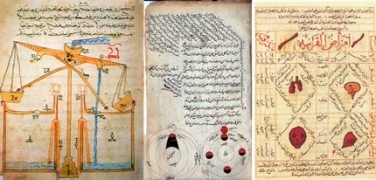

Arabic words in the French language13/01/2021Posted in: CultureRead more

Arabic words in the French language13/01/2021Posted in: CultureRead moreDid you know that there are five to eight more Arabic words than Gallic words in the French language? The Arabic...

-

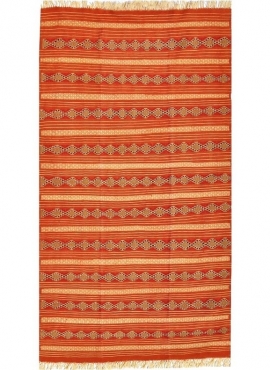

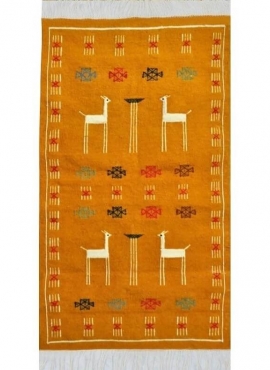

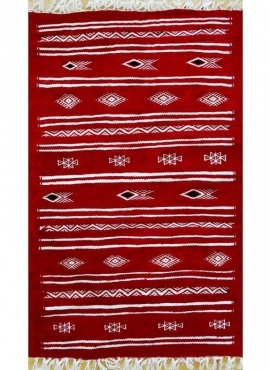

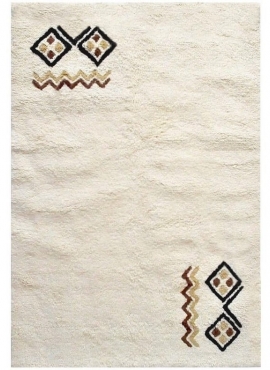

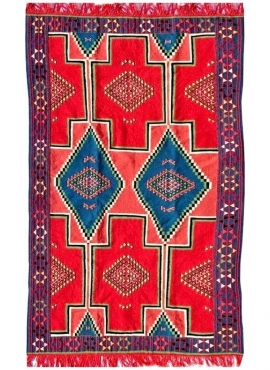

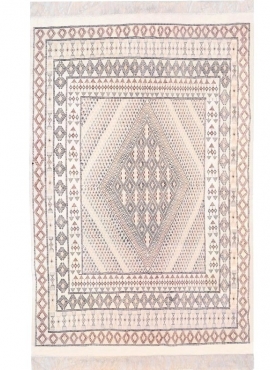

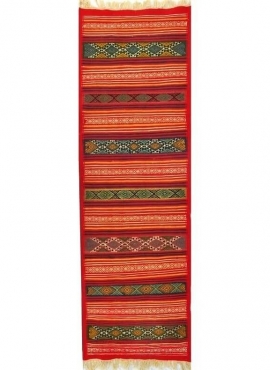

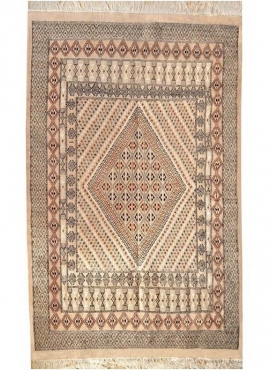

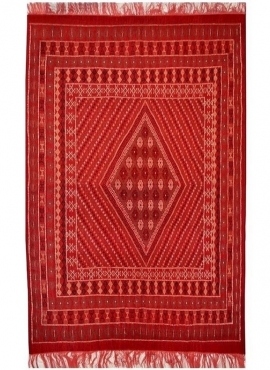

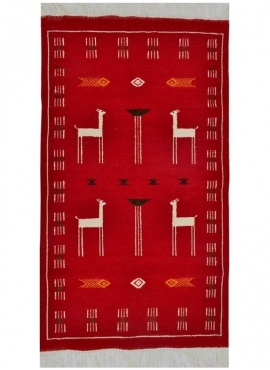

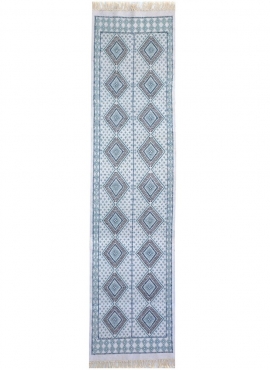

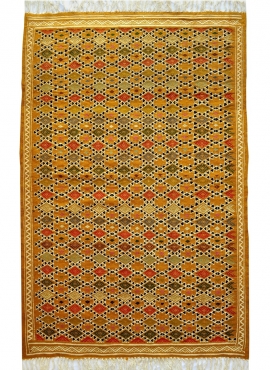

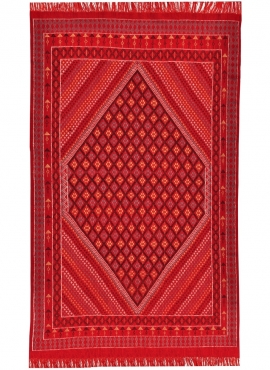

Reviving the Tunisian carpet craftswomanship14/12/2020Posted in: HandicraftRead more

Reviving the Tunisian carpet craftswomanship14/12/2020Posted in: HandicraftRead moreHow to revive the Tunisian carpet craft? A few lines of thought and an overview of the initiatives set up.

Leave a comment